Check through the spec sheet of the Trilab DeltiQ 2, and you'll see a list of some of the most desirable 3D printer components out there. E3D hotend, Duet3D control board, Wi-Fi, App and full compatibility with the multifilament Mosaic.

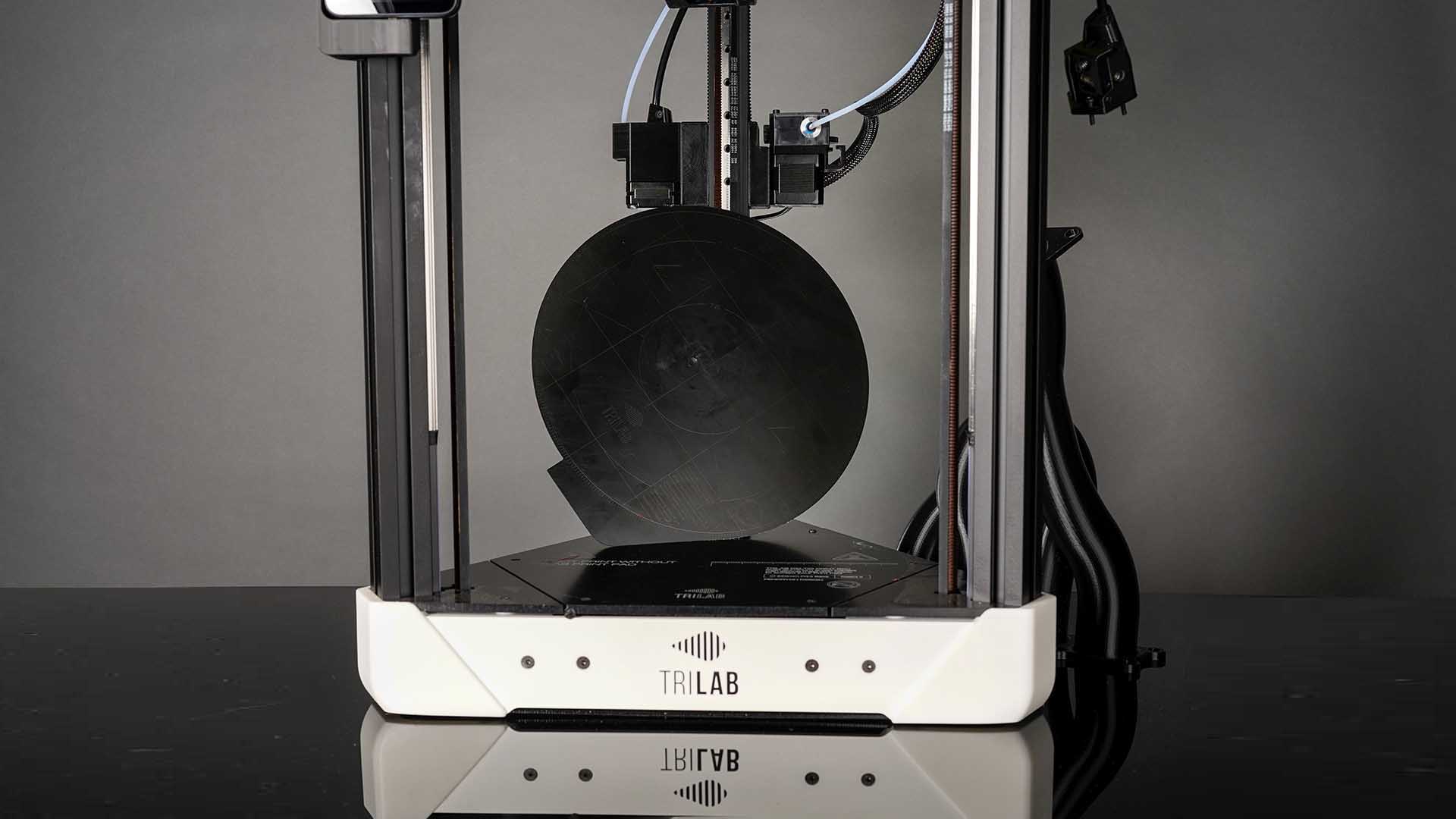

The list of components is impressive, but the stature and design of the DeltiQ 2 make it stand out. Delta 3D printer design is always impressive, marked out by the tower structure and fixed build plate that enables a large print area while retaining a small machine footprint.

The machine's footprint might be minimal at 41 x 50 cm, but at 81cm high, it's far from small. Unlike the more common Cartesian 3D printers, such as the Ultimaker, Delta's utilise a fixed round build plate with the extruder suspended between three arms. As these arms move up and down, the print head moves along the X, Y and Z-axis.

While Delta and Cartesian machines look very different physically, they both use the same basic principle for the print heads coordinates.

- Interested in the Trilab DeltiQ 2? Check out the website here

The DeltiQ 2 is one of the most impressive Delta 3D printers out there and packs in many professional print features that will appeal to professional and business users.

Aside from using some of the most desirable hardware in the construction, the DeltiQ 2 also stands out for having two extruder options, one for standard PLA and PETG and the other for flexibles. It can't print the two materials simultaneously, but a quick swap of components at the tool head, and it's ready to go.

Multifilament printing is possible with the DeltiQ 2, but this requires the Mosaic, a fully supported piece of hardware that can be purchased directly from Trilab.

The DeltiQ 2 Trilab has added almost every desirable feature that you could want when it comes to a 3D printer.

Available in two sizes, I'm looking at the TRILAB DeltiQ 2 with a 30 cm maximum print height. Still, there's also the larger TRILAB DeltiQ 2 Plus that stands at 105cm and 50 cm printing height and the QuadPrint which is either of the two machines with the addition of the multifilament Mosaic hardware.

Design

Delta 3D printers are different by design. The idea being that having the print head suspended from three arms should speed up the print process and cause less print vibration.

Having the print static rather than being raised to the tool head or jilted back and forth should minimalise any print shift, vibration or other issue attributed to having the print moving.

In theory, that all makes sense, and, after firing up the DeltiQ 2, it's apparent that in practice, it works superbly well.

Every 3D print feature you could want and then some

Print technology: Fused Deposition Modelling (FDM)

Print Volume: DeltiQ 2: Ø 250mm (X, Y) × 300mm (Z)

Printhead: E3D V6 all-metal hotend

Extruder: E3D Titan geared extruder, Bowden setup Optional "FlexPrint Edition 2" – TRILAB proprietary remote direct drive extruder for demanding and flex filaments

Print Platform: 5 mm thick aluminium heated print base Swappable magnetic PrintPad sheet with PEI surface PrintPad sheets with alternative surfaces available

Control interface: Wireless 5.45 "IPS "DeltaControl "display, incl. charging dock

DeltaControl app: iOS/Android

WebControl interface: PC/Mac

Connectivity: LAN or WIFI with local or remote access 3x USB: WIFI/LAN module/USB drive/Webcam/Palette 2

Print Monitoring: Multicolor LED indicator for a visual print status overview, Built-in camera with print illumination

Supported input formats: STL, gcode; standard slicers (Kisslicer, Cura, PrusaSlicer, Slic3r, Simplify3D)

Dimensions and weight: DeltiQ 2: 41×50×81 cm / 10 kg

Power: Input 100-240 V, Output 24 V, 250 W

Over the years, I've seen some innovative 3D print features emerge, such as auto filament detection, print monitoring and, of course, auto-levelling print platforms.

Many of these features are now part of my review checklist, which also features a few hardware components that instantly make me excited about what the printer has on offer.

The TRILAB DeltiQ 2 covers the basics, auto print bed levelling, filament detection, multifilament support through the Mosaic, and adds a good scattering of further additions.

You have Wi-Fi printing and a touch screen interface, a web control interface, expandability, E3D hotend, Duet3D control board and a design that has everything covered for business and lab use.

While most other companies look to create a 3D printer that simply prints good quality prints, TRILAB has created a dedicated piece of workshop machinery. The design, interface, integration and expandability means this printer is the perfect solution for business, labs and education.

Features

The features of the DeltiQ read through like a wish list, from the DUET 3D control board, E3D hotend (E3D V6), powerful dual extruders (E3D Titan and Zesty Nimble), one for standard and the other for flexible filaments, app and wireless web interface.

What strikes you as you get into using the DeltiQ 2 workflow is just how joined-up everything is.

You start by designing your model in your chosen 3D application and then exporting it out in the STL, gcode format. That model is then imported into your choice of KISSLICER or PrusaSlicer, and with the DeltiQ 2 profile selected, the print quality options are then selectable.

Once complete, the gCODE file is exported and uploaded to the Trilab WebControl interface, where the file can be queued ready for printing and sent through to the printer wirelessly.

There is, of course, an option to transfer the gCode file manually by plugging in a USB key, or you can plug the printer into the network; the point is all options are there for you to use.

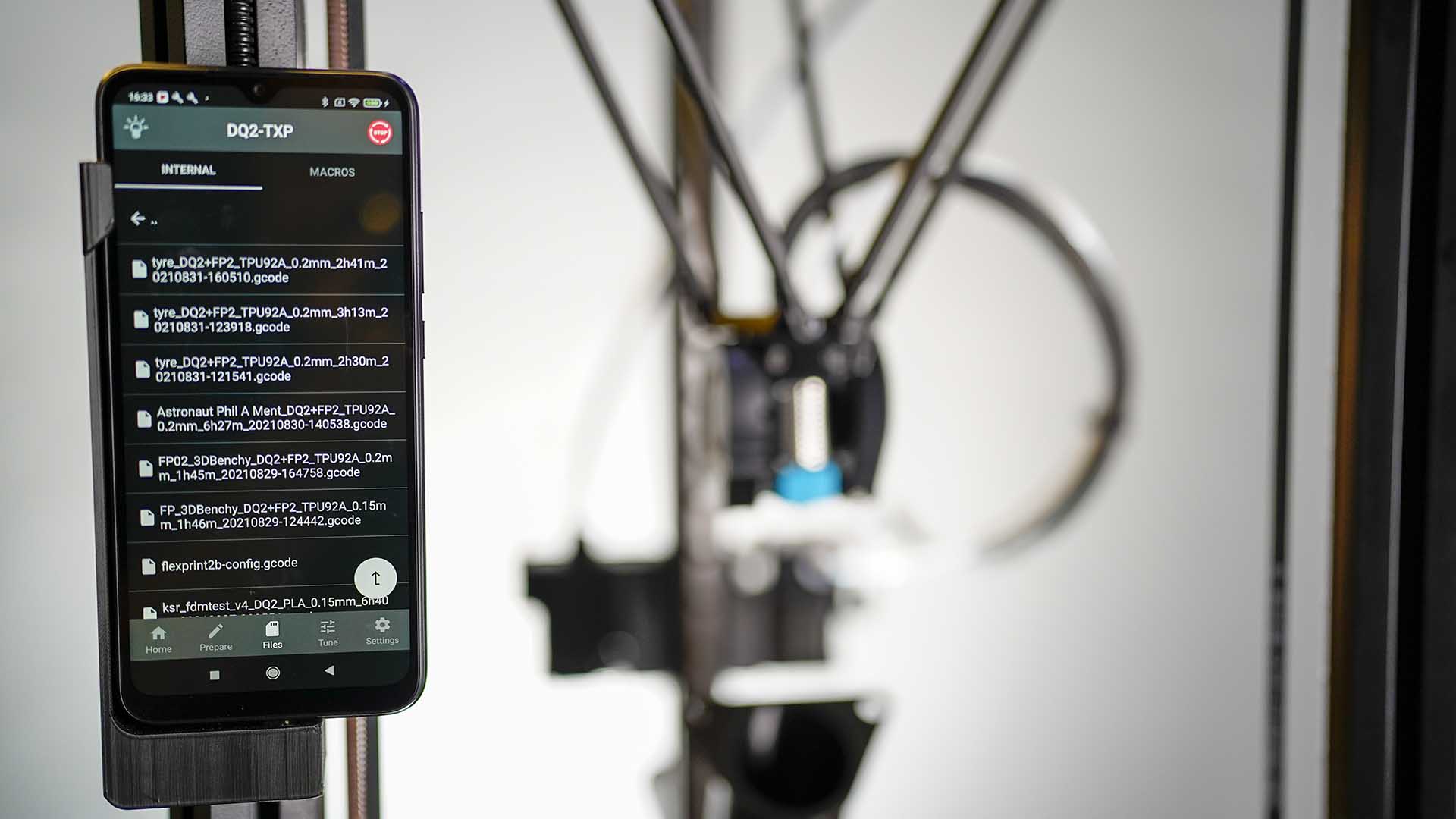

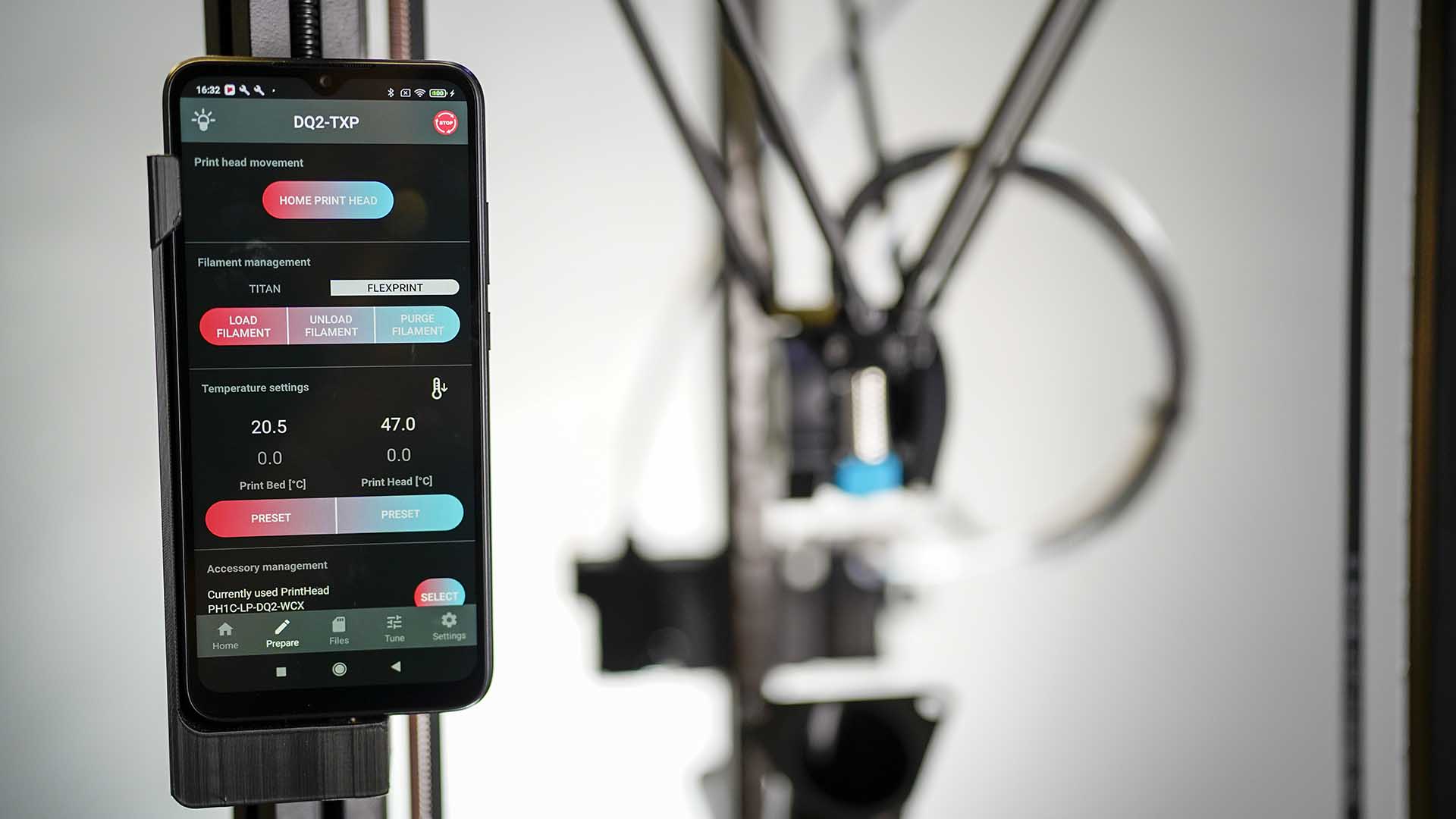

On the machine is the built-in mobile phone that acts as the on machine interface. This is simple and easy to navigate and enables you to set up a fast Wi-Fi network link to your computer. This link is streamlined and one of the easiest that I've come across to set up and use. More importantly, it's incredibly robust. Communication between printer and DeltaControl display (phone is Bluetooth) and there is a special app that can also be run on a user’s Android phone; this is downloadable from Google Play store.

There's also a built-in camera, so if the printer is in the workshop and you want to check how the print is going, log in to the web interface and instantly get real-time video feedback from the printer. Additionally, a webcam or IP cam can be plugged into a USB to create timelapses and HQ pics during printing.

Workflow is a key feature of the printer; from small to medium-sized businesses that require onsite prototyping and manufacture, the DeltiQ 2 looks to be an ideal option to sit alongside other workshop machinery.

Setup overview

Getting started with the DeltiQ 2 is relatively straightforward and with the printer removed from the packaging, print head attached, and after a few other tweaks, the machine is plugged in and powered on.

The main interface for the DeltiQ 2 is provided through an Android mobile phone mounted on the side of the machine. This gives you a clear view of the machine's settings and enables you to connect to a local Wi-Fi network quickly.

The documentation provided by Trilab is second to none. They support the machine's setup, and a getting started service through a video link, which is extremely useful.

The support and hands-on nature of the company is something well worth considering if this machine is to be part of your business.

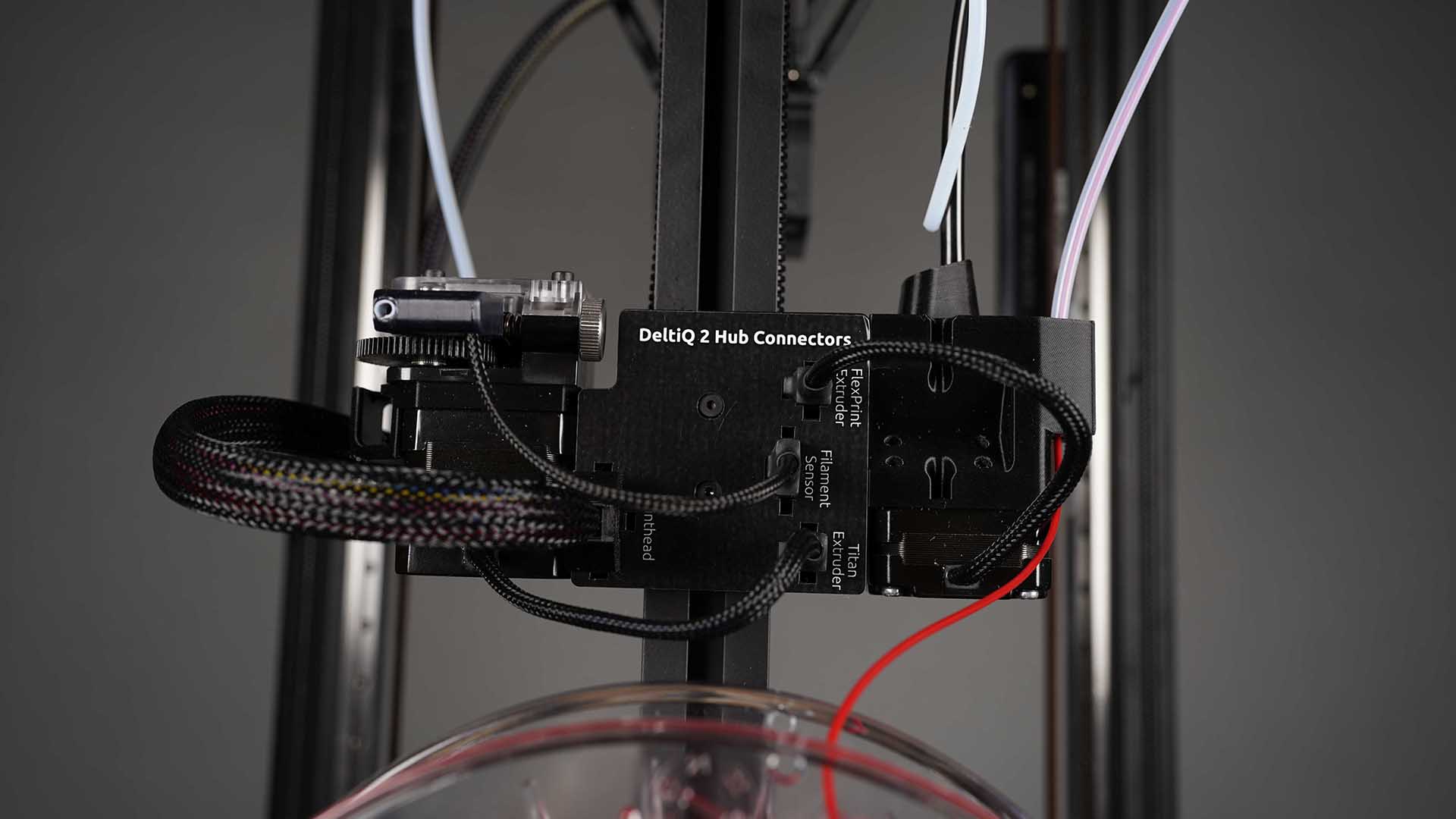

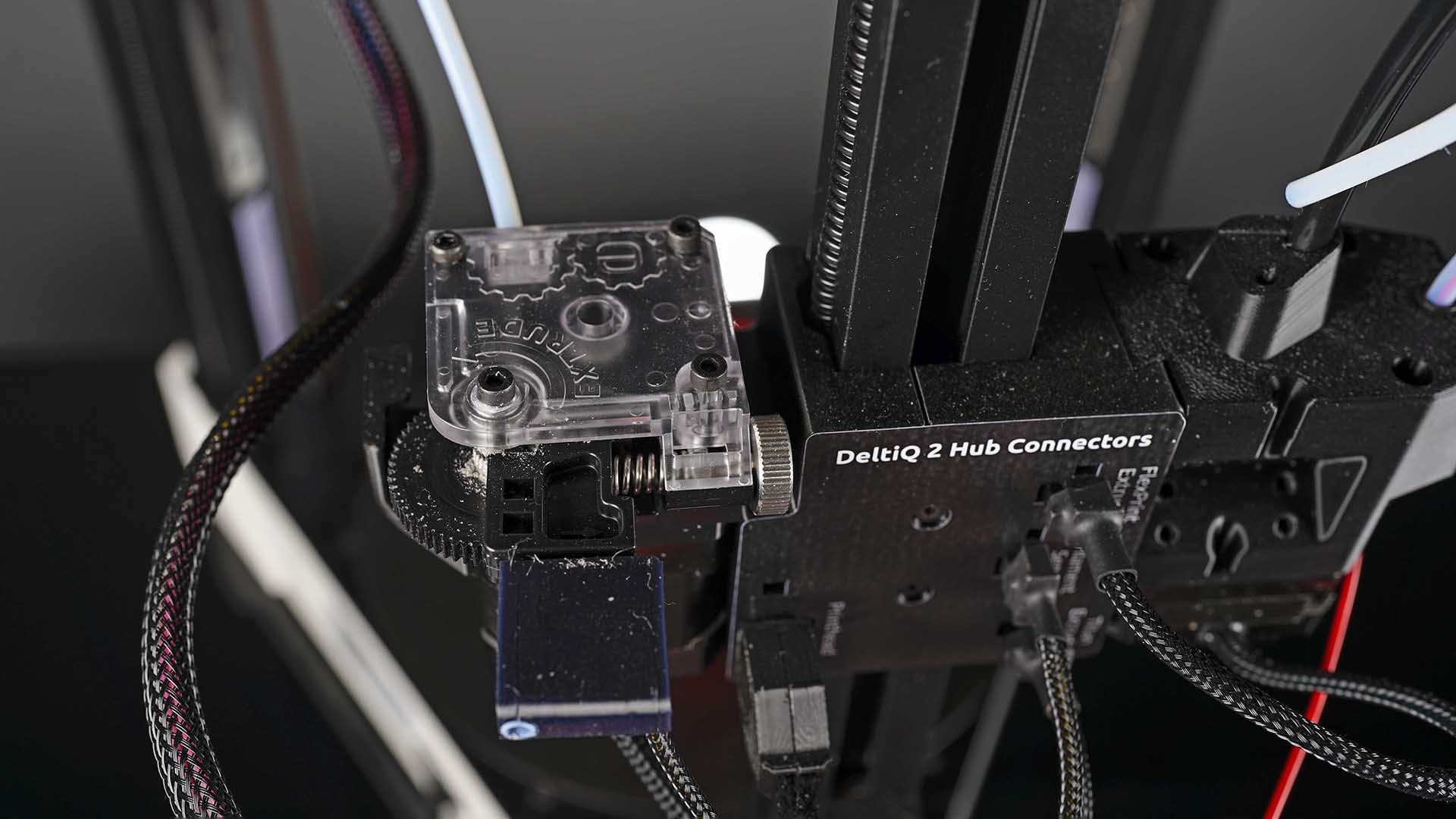

One thing to note is that the DeltiQ comes with two extruders, one for standard filaments and the other for flex materials. While the two extruders exist side by side, the Bowden tube for the flex material is different and needs to be swapped before printing with the flex materials.

Swapping over is a manual process and takes around 15 minutes on the first run; most of this is just double-checking. It really is as straightforward as it seems. After you've done this a couple of times, it's a relatively quick and pain-free process that takes between 3 and 5 minutes max.

Once installed, a profile for the FlexPrint needs to be run, then a quick calibration to check that everything is in order and you're ready to run.

In both cases, for the standard and flex materials, filament loading is all done through the on machine touch screen interface. Again as with the rest of the setup, this is incredibly easy.

A point to make here is that the filament is passed through a filament sensor, so if it does jam or runs out, the machine knows about it and automatically stops the print.

Another aspect of use is that the touch screen interface is actually hosted on an Android mobile phone that connects to the machine through Bluetooth.

This means that if you want to unclip the phone from the machine and move it next to your desk, then you can. It's a very neat and handy feature.

Performance

Only a handful of printers are as streamlined as the Trilab DeltiQ 2, the CEL-UK RoboxPro, Ultimaker S3 and Raise3D E2 come to mind.

In use, it's apparent that this is a printer designed for the professional market; it's fast at printing large objects with excellent dimensional accuracy.

However, as the test progressed, I found that if you wanted to get the best from the printer, you needed to make slight tweaks to the profiles depending on the type of model. To be honest, this is the case for most printers, but here a little closer attention is needed.

For instance, printing with the default profile in PrusaSlicer would gain excellent results for large objects where accuracy was key. However, printing one of the test models or an intricate model and stringing could be an issue. This turned out to be due to how PrusaSlicer handles the retraction settings.

Switch over to KissSlicer, and the stringing is all but illuminated, and the results are as clean and crisp as I've seen from any printer.

Looking at day-to-day printing and starting with printing the stress test models, the DeltiQ 2 flys through 3DBenchy at all settings. So little to report on issues with quality for any of the settings.

Moving on to the Autodesk and Kickstarter FDM 3D printer assessment, and at first, the results struggled to live up to the quality that I had been seeing from the results of other models.

A switch of slicer from PrusaSlicer to kissSlicer made a difference with the profile better suited to the finer details of the print. What was instantly apparent was the dimensional accuracy of the model.

Looking at other standard test models and across the board, results in all cases are good, with a fine layer structure and surface finish.

The team at Trilab sent through the huge exhaust pipe model, which takes a couple of days to print and demonstrates what this printer is capable of.

For such a larger model, printed over a long period, the results are incredibly good, there are few surface blemishes, and overall accuracy is once again excellent.

The large model printing results highlight the big selling point of any Delta machine; they can print big reliably. Without the print platform moving, the print head does all the work, which means that while other 3D printer designs may struggle with taller prints, the Delta style excels.

The design also means that you can change how you print; supports are still extremely important. However, you can think about support differently. As the print is static, it's less affected by vibration or movement, which means you can be a little more frugal with the support structure and how they are applied. This does take some time to master in the same way as adjusting from FDM to SLA printing.

It also means that as you delve into your chosen slicer, PrusaSlicer or KISSlicer, and really fine-tune the settings for your intended print, the result just get better. You do need to be a little more familiar with the slicer settings and options that you would with other printers.

This once again highlights the intended market for the DeltiQ 2. The prints you can achieve are outstanding, especially for prototyping or small production run accuracy, but you do need to know what you're doing. Once again, this is where the excellent support from the company comes into play.

Print standard or FlexPrint

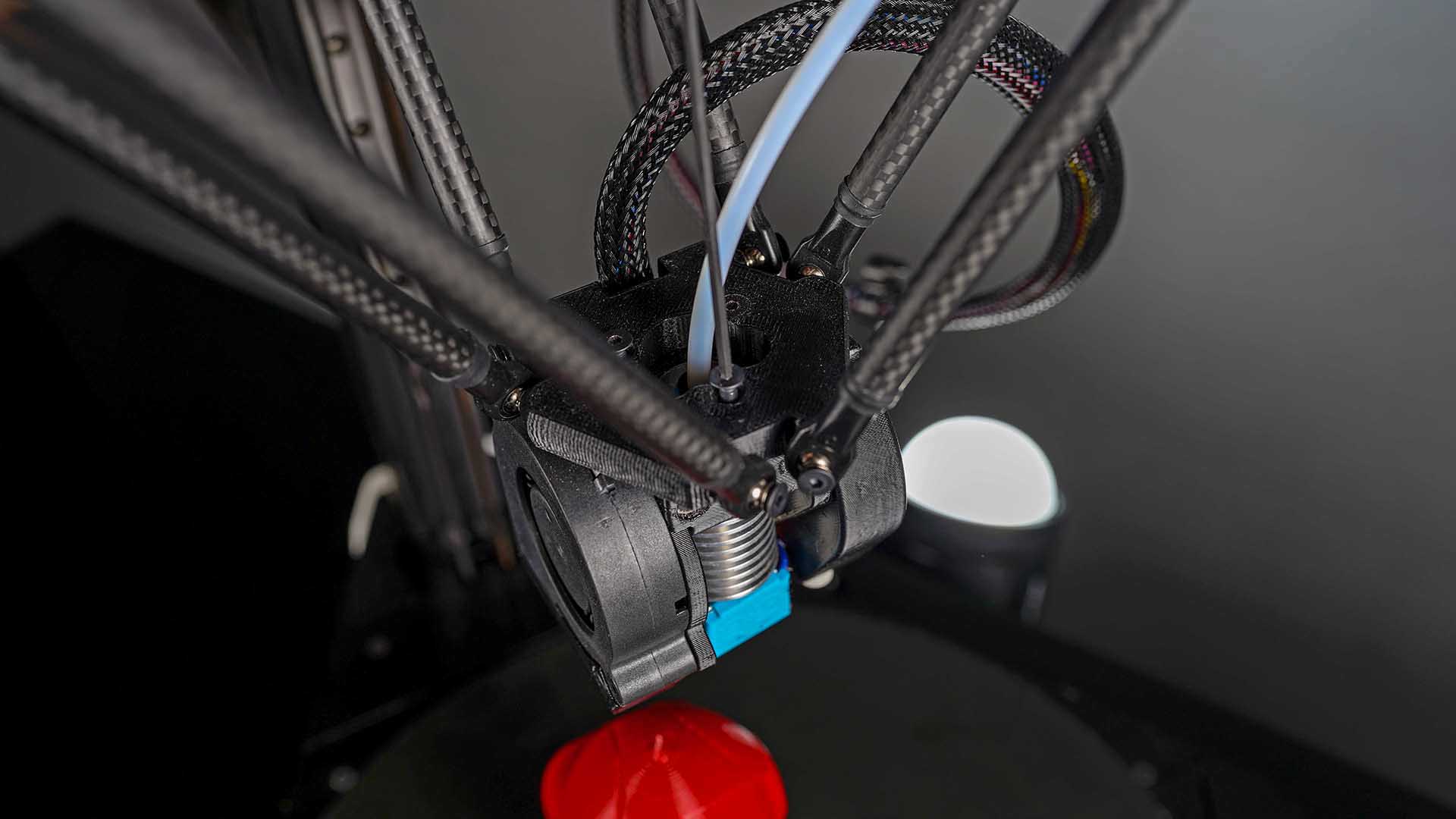

One of the biggest selling points of the DeltiQ 2 and indeed its USP is that it features two extruders, the E3D Titan, which is ideal for PLA, PETG or CPE.

More advanced materials can also be used, such as ABS/ASA, Nylon or Nylon with CF, by simply adding a hardened nozzle to the E3D V6. All standard stuff.

What's less standard is that the second extruder is the direct drive (formally based on the original Zesty Nimble remote direct drive). The new version of FlexPrint 2 is based on TRILAB proprietary remote direct drive extruder. While the filament is still fed through a tube, it is pulled through rather than pushed. The extruder is clever, utilising a remote direct drive that keeps the motor away from the head but employing a drive cable still operates the two rotating rods of the remote direct drive extruder.

This means that with a swap of the components on the tool head, you can then print TPU or TPE.

Ordinarily, to print with a flex material requires a bit of tinkering with the machine, and sure enough, a little is required here. But once done, the use of the machine remains much the same, and the printing techniques are straightforward.

Best of all, the reliability of the flex printing is excellent and on a par with the standard filaments. I've tried countess flex solutions, and all have worked to a degree but had issues; here, Trilab seems to have created a solid and reliable system.

Print quality

Dimensional accuracy - score of 5

- Target 25 = X: 24.96mm / 0.04mm Error | Y: 25.05mm / 0.05mm Error

- Target 20 = X: 19.99mm / 0.01mm Error | Y: 20.05mm / 0.05mm Error

- Target 15 = X: 14.95mm / 0.05mm Error | Y: 15.05mm / 0.05mm Error

- Target 10 = X: 10.05mm / 0.05mm Error | Y: 10.15mm / 0.15mm Error

- Target 5 = X: 5.14mm / 0.14mm Error | Y: 5.15mm / 0.15mm Error

X Error Average = 0.058

Y Error Average = 0.09

X&Y Error Average = 0.074

Fine Flow Control - score of 2.5

Fine Negative Features - score of 5

Overhangs - score of 3

Bridging - score of 5

XY resonance - score of 2.5

Z-axis alignment - score of 2.5

Adding up the totals gives a final score of 25.5 out of 30.

Final verdict

The Trilab DeltiQ 2 is one of the most impressive machines that I've used. The unconventional Delta design works well as the theory would have you believe.

For me, the machine's small footprint is the first major point of approval, with it easily finding space on my workbench, the only requirement being plenty of headroom for its 81cm height.

Out of the box, the setup process is quick and easy - there is little to the setup of the complex looking machine that will cause an issue, and if you're unsure, then a quick email to support and they get back to you in good time.

When I first saw the DeltiQ 2 a couple of years ago, I was impressed by the looks and quality of the company's prints on their stand. Now two years on, the machine has evolved further and brings a finesse in printing that few other machines can offer.

In this review, I have looked at the printer in isolation, with the unique combination of the standard and flex extruders, but it's worth considering there's more.

Trilab has heavily invested in integration, and the machine can be used seamlessly with the mosaic multifilament system. I've seen this in action, and it's impressive, enabling multifilament and material printing on one printer.

While I highly rate the DeltiQ 2 as a quality printer, it's not suited to everyone. You need to have some knowledge of 3D printing and the Slicer software you opt to use. This is not a failing of the system, more that it enables you to fine-tune the machine and the prints to your style of use.

Most slicers and printers meet in a one size fits all approach, and to be honest, you don't really have an option to approach the likes of supports and structures in any other way.

With the DeltiQ you do, no moving build plate means that the models stay put, and less support structure is required. These supports need to be created manually, but it doesn't take long to skill, and the payoff is a huge saving in filament and print times.

There's also the subject of material support as this is an open printer, so not suited for ABS or nylon. However, some filament options will negate some of the warping and other issues you may get from trying to print with these materials. However, the DeltiQ 2 is designed for the latest materials, of which there is a huge selection to choose from.

If you're looking for a professional 3D print solution, then the Trilab DeltiQ 2 is incredible.

- We've also highlighted the best 3D printer

from TechRadar - All the latest technology news https://ift.tt/38Jfke1

No comments:

Post a Comment